MIMAKI PRINTERS

FEATURES & BENEFITS

Built upon the proven technology of Mimaki’s industry-leading flatbed printer, the JFX200-2513 EX offers expanded capabilities with greater productivity and functionality. New features include a draft mode that enables a maximum print speed of up to 12 boards per hour and three staggered printheads that allow for simultaneous printing without sacrificing speed, even when using white and clear inks. This model offers faster mechanical motors and a vacuum foot pedal, giving the user the ability to load or unload various substrates quicker and more effectivity.

Benefits of the Mimaki JFX200-2513 EX

- Landscape-oriented table can print on one 4’ x 8’ board or a variety of pre-cut pieces, and onto objects up to 2” thick

- Dual-zoned vacuum table and user-adjustable layout pins

- Nozzle Recovery System and Nozzle Check Unit

- Variable Dot Technology and Mimaki Advanced Pass System (MAPS) for smooth gradients and solids

- Greenguard Gold UV-LED inks in 4 and 6 color configurations plus Clear, Primer and White

- Updated RasterLink6 Plus to support 2.5D textured print workflows

- USB/Ethernet connectivity

Highlights of the Mimaki JFX200-2513 EX

2.5D Print Function Enables Easy Creation of Textured Graphics

Compatible with RasterLink6 Plus software, 2.5D printing allows users to create dimensional textured graphics up to 0.5 mm in height using greyscale. These semi-stereoscopic graphics, such as a beveled polygon or a bowl shapes, add a new look and feel to the finished application, enhancing its appearance while increasing its value. Combined with Mimaki Clear Control, this print function also takes full advantage of Mimaki’s LUS clear inks to remove bubbles and create sharper edges, delivering textured graphics that look and feel like the objects being represented.

Landscape-Oriented Table

The landscape-oriented table can print an entire 4-foot by 8-foot piece, or print multiple smaller boards using the two selectable vacuum zones. It can also print to pre-cut, irregularly-shaped pieces.

Layout Pins

Standard layout pins and scale ensure board alignment, which is particularly useful when printing full bleeds.

Variable Drop Printing

The advantage of variable drop printing is most apparent when printing color gradations in light or pastel colors.

Anti-Banding Technology

Variable drop printing combined with Mimaki Advanced Pass System technology ensures precise and accurate print quality throughout the printing process, greatly reducing the appearance of banding and resulting in a smoother image.

White, Primer and Clear

Add White ink to print onto clear acrylic to create backlit panels or to print on wood, metal, or non-white surfaces. Mimaki Circulation Technology regularly circulates White ink between the supply and the printhead to prevent settling. Primer helps the ink adhere to surfaces such as glass. Clear ink adds ‘pop’ and protection to finish a piece.

UV-LED Technology

Mimaki’s UV-LED system uses less energy than other UV types, has a longer life and can print into media that could be damaged by higher-heat systems.

Direct-to-Media Printing Even on to Thick Media

Images can be printed directly onto rigid media up to 50mm thick, providing great versatility and a wider range of potential applications.

What you can do with the Mimaki JFX200-2513 EX

- Signs and posters

- Point-of-purchase displays

- Exhibition graphics/signs

- Backlit panels

- Interior decor

- Packaging prototypes

- Specialty and industrial applications

- Acrylics

- Polycarbonates

- PVC

- Glass

- Aluminum

- Metal

- Polyester

- Foam board

- Styrene

- Wood

- Stone

- and more…

Attention should be paid to ink adhesion, even though it will print onto almost any substrate, levels of adhesion do differ between materials. The range of possible applications is practically limitless. A selection:

- Art reproduction

- Backlit graphics

- Construction signs

- Displays

- Rigid packaging

- Lenticular (printing with 3D effects)

- ID cards

- Logos (3D)

- Operation panels

- Promotional items

- Relational gifts

- Accessories

Technical overview of the Mimaki JFX200-2513 EX

Print system | On-demand piezo |

Max print area | 98.4” W x 51.1” L (2500 x 1300 mm) |

Media thickness | 1.96 in (50 mm) |

Print resolutions | 300, 450, 600, 900, 1,200dpi |

Max print speed | 376 SqFt/Hr (35 SqM/Hr) / in draft mode |

Absolute accuracy | +/- 0.01” (0.3 mm) or +/- 3% from specified print distance |

Repeatability | +/- 0.008” (0.2 mm) or +/- 1% from specified print distance |

Ink type | Mimaki LUS-150 UV ink: For balanced adhesion and flexibility- C, M, Y, K, Lc, Lm, W, Clear |

Ink capacity | 1-liter bottle, 250 mL bottle |

Flatbed table | Vacuum system (standard), 2 user-selectable zones |

Certifications | VCCI Class A, FCC Class A, ETL UL 60950 CE Marking (EMC, Low voltage, Machinery directive) CB Report, RoHS |

Operational environment | Temp: 59˚ – 86˚ F (15˚ – 30˚ C) |

Max media weight | 110.2 lb / SqFt (250kg/SqM) |

Interface | USB 2.0, Ethernet |

Power supply | AC 200-240V, 50/60 Hz |

Power Consumption | 2.88 kVA |

Dimensions (W x D x H) | 173.2 x 96.4 x 49.2 inches (4,400 x 2,450 x 1,250 mm) |

Weight | 1433lbs. (650 kg) |

Benefits & Features:

Engineered for Industrial Printing Workflow

The Mimaki UJF-7151 Plus II UV-LED printer is the next generation model in the world’s best selling UJF Series line. This state of the art printer is geared for high accuracy, high image quality, and industry-leading productivity and stability.

- Print area: 28" x 20" ; up to 6" thick!

- Load capacity has increased from 22lbs to 66lbs!

- Capable of printing up to 1800dpi

- Print speeds up to 190% faster than the previous model!

- (8) Print heads

- Eco-friendly with low VOC, Greenguard Gold Certified UV-LED inks

- Pair with our desktop 3D printer to produce jigs, molds for thermoforming or custom molds!

Core Technologies:

- Waveform Control

- Mimaki Advanced Pass System

- Nozzle Check Unit

- Nozzle Recovery System

- Mimaki Bulk Ink System

- Mimaki Circulation Technology

- Mimaki Fine Diffusion

Specifications:

- Printheads: (8) on demand piezo heads in a staggered array

- Print resolutions: 1800dpi

- Print speed (4-color mode): 22-beds / hour

- Maximum print area: 28.7"

- Maximum media thickness: 6.02"

- Maximum media weight: 66lbs

- Ink type: LH100,LUS120, LUS350 (ink not included)

- Interface: Ethernet 1000Base T, USB2.0 High Speed

(For a FULL specifications worksheet, please click here!)

Applications:

- Carton boxes

- ADA Braille Signs

- Pens

- Trophies

- Water bottles (with Kebab)

- Keys

- Mobile phone covers

- Thermoforming

- Industrial parts

- Serial plates

- Just to name a few!

Features & Benefits:

Mimaki UJF-7151 Plus UV-LED printer is the next generation model in the world’s best selling UJF Series line. Its design and technologies enable sign, specialty graphics, and award and personalization companies to realize the benefits of digital printing with higher margins and lower production costs, without compromising quality. The UJF-7151 Plus printer is a multipurpose, wide-format model that can print on a variety of substrates including plastics, metal, wood, leather and glass onto materials up to 28” wide x 20” long and 6” thick.

Mimaki UJF-7151 Plus Overview

- Create specialty items, novelties, awards, custom pieces and more

- Ideal for screenprinters and pad print shops that want to add one-off or custom digital print operations

- Print on media up to 28” wide x 20” long (710 x 510 mm) and up to 6” thick (153 mm)

- Exceptional print quality

- Mechanical structure reduces vibration, which increases ink drop accuracy

- MAPS4 technology reduces banding

- MFD1 patented dithering technique in RasterLink6 software enhances image quality

- New UV-LED curing system delivers high quality results

- Variable dot printing delivers high quality with smooth gradients

- Low-energy UV-LED lamps enable printing on heat-sensitive substrates

- Ink versatility for use in various applications from hard surfaces to flexible media

HIGHLIGHTS OF THE MIMAKI UJF-7151 PLUS

EXCEPTIONAL PRINT QUALITY.

- Unlike conventional models, the print table moves the substrate under the staggered print heads, using Mimaki’s exclusive ball screw technology to reduce vibration and increasing ink drop accuracy.

- Mimaki Advanced Pass System 4 (MAPS4) technology reduces banding and produces smoother images.

- Mimaki Fine Diffusion 1 (MFD1) patented dithering technique in RasterLink6 RIP software enhances image quality.

- A new UV-LED curing system controls lamp power and curing time for higher quality results. When using clear ink for a topcoat, the additional control delivers near-flawless glossy results by preventing dust adhesion and air bubble formation.

- Variable dot printing produces smoother gradients and quartertones.

- Waveform control jets each ink droplet at an optimum angle to maintain ink droplet formation and shape.

WHAT YOU CAN DO WITH THE MIMAKI UJF-7151 PLUS

- Smartphone covers

- Awards

- Personalized writing instruments

- Wayfinding / safety signage

- Business card holders

- Water bottles

- Decorative panels

- Packaging

- Binder covers

- Identification cards

- Announcement boards

- Wedding specialties

- Membrane switch panel

- Industrial applications

- and more…

Features & Benefits:

THE MIMAKI JFX200-2513 GO BEYOND

- Landscape-oriented table can print on one 4’ x 8’ board or a variety of pre-cut pieces

- Table size 98.4” W x 51.1” L (2500 x 1300 mm)

- Objects up to 2.0” thick (50 mm)

- Printing speeds up to 269 SqFt (25 SqM) per hour

- Up to 8 – 4’ x 8’ boards per hour

- Layout pins ensure proper media alignment

- High quality print resolution of up to 1,200 dpi

- Landscape-oriented table can print on one 4’ x 8’ board or a variety of pre-cut pieces

- Table size 98.4” W x 51.1” L (2500 x 1300 mm)

- Variable dot printing and Mimaki Advanced Pass system deliver smooth gradients

- Zoned vacuum table holds media flat

- UV inks supplied in high-capacity 1 liter bottles

- White, Clear, and Primer available

- LUS-150 inks are flexible up to 150%

- LH-100 inks offer high scratch and chemical resistance

- Nozzle Check Unit and Nozzle Recovery System

- Low-energy UV-LED lamps last five years or more

| Print system | On-demand piezo (2 printheads in a staggered configuration) |

| Max print area/ Max media size | 98.4” W x 51.1” L (2500 x 1300 mm) |

| Media thickness | Up to 2.0” (50 mm) |

| Print resolutions | 300, 600, 900, 1200 dpi |

| Max print speed | 269 SqFt/Hr (25 SqM/Hr) |

| Absolute accuracy | +/- 0.01” (0.3 mm) or +/- 3% from specified print distance |

| Repeatability | +/- 0.008” (0.2 mm) or +/- 1% from specified print distance |

| Ink type | Mimaki LUS-150 UV ink: C, M, Y, K, W Mimaki LH100 UV ink: C, M, Y, K, W, Clear Mimaki PR-100 UV Primer |

| Ink capacity | 1-liter bulk ink system standard |

| Flatbed table | Vacuum system (standard), 2 user-selectable zones Layout pins (standard) |

| Operational environment | 98.4″ × 51.2″ (2500 × 1300 mm) (w x d) |

| Media weight | Temp: 59˚ – 86˚ F (15˚ – 30˚ C) 35-65% RH (non-condensing) |

| Connectivity | USB 2.0 |

| Power supply | AC 200-240V, 50/60 Hz |

| Dimensions (W x D x H) | 173.2 x 96.4 x 49.2 inches (440 x 245 x 125 cm) |

| Weight | 1389 lbs. (630 kg) |

Features & Benefits:

Super-wide or Dual-Roll Capability

| The UJV55-320 printer feeds media up to 127.9 inches (3.2 m) wide for the largest of graphics and panels. It's also possible to simultaneously print onto two 60-inch (1.52 m) rolls. This dual-roll capability can double the productivity of a shop, with each rolls printing the same set of graphics, or completely different jobs. |

STUNNING BACKLIT CAPABILITIES

| High density UV Inks give greater "Blockout" than other print methods allowing for superior vibrancy in backlit applications. Additionally, three-layer printing with color + white + color allows for high fidelity prints that serve as as frontlit by day and backlit by night. The built-in lightbox allows for accurate proofing of your printed backlit images on the fly. |

INCREDIBLE PRINT QUALITY

| The UJV55-320 features multiple print modes, ranging from the high-production 300x600 dpi mode through to 1200x1200dpi for ultra-high quality. The Mimaki Advance Pass System 4 (MAPS4) technology on the UJV55-320 features virtually eliminates banding for greater image quality. Variable drop printing produces smoother gradients and improves the smoothness of subtle colors such as skin tones. |

FEATURES FOR HIGH CAPACITY PRODUCTION

| 4 Print Heads are arranged in a staggered configuration for high-speed printing. High-capacity ink reservoirs hold up to three liters of ink for long runs, plus white ink is circulated at regular intervals to prevent pigment sedimentation, allowing for more stable printing. Mimaki's Nozzle Checking Unit detects clogged nozzles during printing and automatically performs cleaning. If the cleaning does not recover the missing nozzles they are automatically remapped before printing continues. |

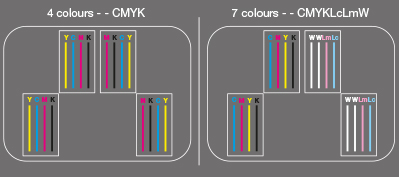

HIGH PERFORMANCE, HIGH FLEXIBILITY UV INK

| The UJV55-320 printer uses Mimaki’s new LUS-120 UV ink – available with Light Magenta, Light Cyan and White. LUS-120 UV ink offers excellent scratch resistance and provides up to 170% flexibility, even on soft media such as (non-laminated) banner materials. Fast curing, LUS-120 ink is an excellent choice for high- performance UV-LED printing. |

APPLICATIONS FOR THE THE UJV55-320 PRINTER

WITH LUS-120 UV CURABLE INKS

|

MIMAKI UCJV300-160 UV LED PRINTER/CUTTER (64" WIDE)

Benefits & Features:

UNRIVALED VERSATILITY

The UCJV300-160 is the worlds only 64" wide LED UV Curable print/cut solution. Being UV Cured, LUS-170 inks give a wider range of media compatibility than any other ink technology. White inks extend this range even further, allowing printing on clear, metallic and even solid colored media. With contour cutting built in, the UCJV300 is the machine that suits nearly every graphic application...

- Highest media versatility with unparalleled scratch resistance

- Print and cut capability in one unit

- White Ink and 5-Layer modes allows for second-surface printing and double-sided clear decals

- Clear Ink allows unique raised and "spot-gloss" effects

- Instantly-cured prints for shorter turnarounds and additional cost savings

- Eco-friendly with low VOC, GREENGUARD Gold certified UV-LED inks

- 3M™ MCS™ Warranty on LUS-200 inks and Avery Dennison™ ICS™ Performance Guarantee on LUS-170/LUS-200 inks

- RIP software RasterLink6 Plus with ID cut function included

Specifications

- Printhead: Two industrial-grade, in-line on-demand piezo heads

- Print resolutions: 300dpi, 600dpi, 900dpi, 1200dpi

- Cut Speed: 16.5″ sec (42.0 cm/sec)

- Maximum Cut pressure (Metric grams): 450g

- Maximum print area: 63.4"

- Maximum media width: 63.8"

- Maximum media thickness: Up to 1mm)

- Maximum media weight: Up to 88.2 lbs

- Ink type: U.S. & Canada - LUS-170 and LUS-200 (C,M,Y,K,Wh, Cl)

- Ink package size: 1L bottles

- Interface: Ethernet cable or USB2.0 cable

- Power supply: Single phase AC100~120V/200~240V (+/- 10%), 50-60Hz (+/- 1Hz)

- Operational enviroment: Temperature 20-30 degrees C with Humidity at 35-65% RH (non-condensing)

- Printer size: 103.5″ x 30.6″ x 58.1″

- Assembled printer weight: 414.5 lbs